Developing Solutions for Companies Across the Globe

Inventory Management System

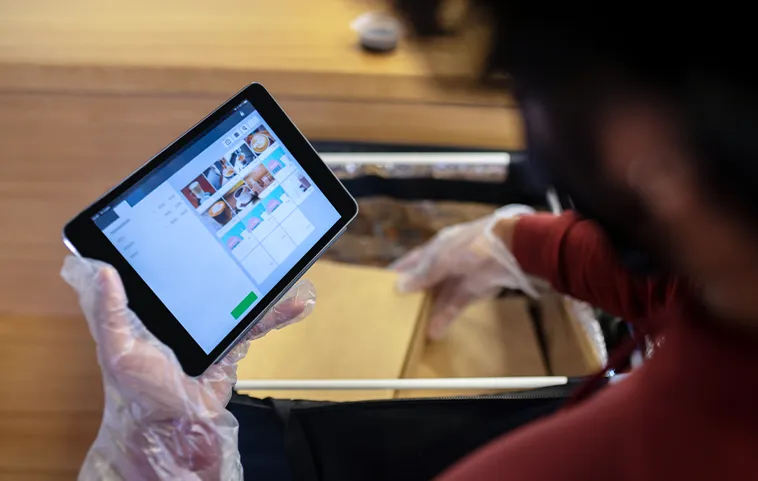

Trinity’s solutions provide real-time tracking, concise workflows, and comprehensive analytics, ensuring inventory accuracy.

Achieve Maximum Asset Control

Track & Manage Inventory With:

Accurate Asset Tracking

Accurate Asset Tracking Predictive Maintenance

Predictive Maintenance Barcode Scanning & RFID

Barcode Scanning & RFID Label Printing

Label Printing Quantity on Hand

Quantity on Hand Physical Inventory

Physical Inventory

How We Enhance Your Inventory Processes

Our solutions ensure seamless operations by automating inventory and asset tracking, providing real-time data insights, ensuring compliance, and improving workflow. These features allow your team to focus on core activities, adapt quickly to changes, and deliver exceptional results, even in remote or low-coverage areas.

Book a Free Consultation

Case Studies

Trinity developed a custom user-facing interface, to complement the existing application, eliminate constraints and streamline the overall process. Ultimately providing an effective, cost-conscious solution within a very short amount of time.

Read More About This Case Study

- Users can now conduct inventory transactions in a quick, easy to use custom interface.

- The amount of data entry and clicks in the process was drastically reduced.

- Additional error checking added an extra layer of governance and security to the process.

Trinity developed a Quickbase application to track, manage, and report on the entire workflow. ARC’s Quickbase ERP tracks everything from customer orders to supplier purchases and all the processes in between. ARC sees Trinity as a lifetime partner to provide and implement the solutions they need as they continue to grow.

Read More About This Case Study

- Automated the reporting of metrics to allow for better decision-making while also cutting down on data entry errors.

- Reduced the number of applications used to manage the business from 5 applications to 2, with Quickbase and QuickBooks communicating with one another.

- Removed the need for ARC to hire an additional employee for data entry and bookkeeping.

- Eliminated the data entry burden on key managers by an average of 10 hours a week.

Trinity developed a Quickbase application to track results and report on performance. The solution included a custom mobile application with integrated barcode scanning, time clock integration, and a Bluetooth portable printer to print the work order for each vehicle. Detail Manager now has quality control oversight of every vehicle.

Read More About This Case Study

- Improved overall vehicle turnaround time by 25%.

- Labor and chemicals can now be tracked for improved performance, saving 10%.

- Dealerships know the cost of the detail shop and performance trends.

- Inventory management for chemicals allows for easy reordering, saving employees' time.

Trinity began by visiting Willow Run’s facility in order to understand their business processes in detail and see how the company operated on a daily basis. This intimate understanding of the business yielded a highly tailored application that handles everything from sales orders and fulfillment to inventory management and purchasing. A real highlight for Willow Run was a custom “Buying Module” that allows the team to more efficiently and accurately build purchase orders across dozens of vendors based upon actual upcoming order needs.

Read More About This Case Study

- Total confidence in inventory and procurement processes.

- Inventories are highly accurate meaning customers rarely place orders that cannot be fulfilled.

- Buyers are able to make purchasing decisions more easily using actual sales data.

- Purchase orders are created automatically across all vendors, saving buyers time and reducing mistakes.

Trinity assisted by combining all the existing manufacturing applications into a single Quickbase app and enhancing and optimizing workflow processes. The new application provided much more visibility and management oversight over all assemblies being manufactured in house.

Read More About This Case Study

- Unified table structure for easier reporting and management purposes.

- Greater visibility into the status of all assemblies being built and tested.

- Developed a new process for work order creation that dramatically reduced the data entry needed.

- Reduced the time needed to create new assembly types.

Trinity was brought in to work with the CAVCOMM team through business process improvement first and then develop a solution to meet those process changes. Trinity delivered a full solution to manage the entire business workflow for CAVCOMM. From office staff to the sales team to project managers to the team members that do the fiber installation, they can all now update all details of the job pertaining to time, materials, labor, and documents.

Read More About This Case Study

- Full job estimating, costing, and invoicing

- Tracking of all inventory from receipt to installation including rolling inventory

- Mobile application to track all team members exact job time, materials used and documents they can view and mark up

- Job status tracking and management

Trinity developed a robust solution in Quickbase that allowed the integration of a Bluetooth barcode scanner, the ability to check in and check out multiple assets to a given resource, and real-time and historical logging of asset assignments. This allowed Oyster to quickly track assignments, repairs, and lost and stolen assets.

Read More About This Case Study

- Completely streamlined and simplified asset management process.

- Barcode scanner integration saving countless hours of manual entry.

- Ability to see all inventory’s current status and condition much faster.